Relevant specifications for metal expanded net curtain wall:

1、 Steel mesh GB / T 33275 – 2016

2、 Barriers - Part 6: steel mesh (GB / T 26941.6-2011)

3、 Steel mesh QB / T 2959 - 2008

Note: 1 The English standard name of "steel plate net" in the national standard is expanded steel net, and its term is defined as "hole net produced by mechanical cutting, extension and expansion of metal plate or coil". The term uses "metal", not specifically "steel plate", which conflicts with its English standard name.

2. The national standard only specifies the steel mesh, but does not specify the expanded mesh of other materials, such as aluminum alloy.

3. The bearing capacity of steel grating plates is clearly specified in steel grating plates and accessories Part 1: steel grating plates (Yb / t4001.1 - 2007).

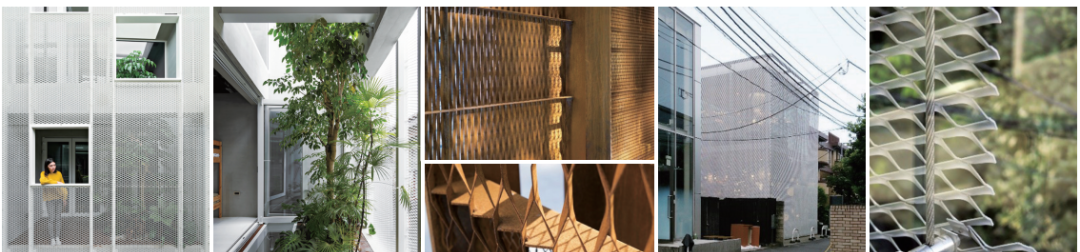

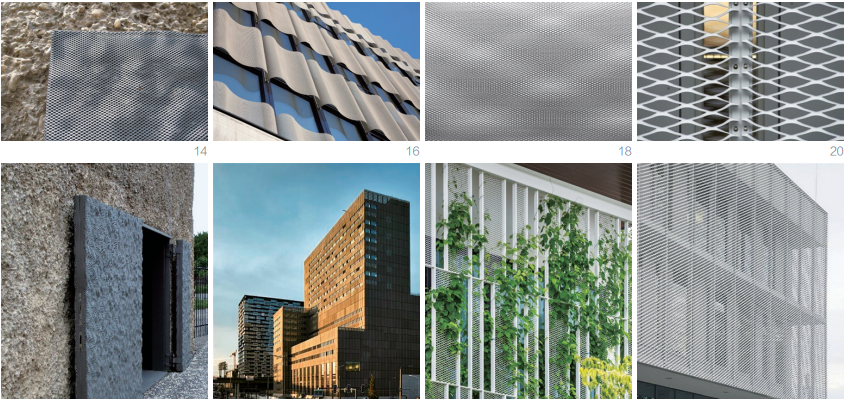

1、 Introduction to metal expanded mesh materials

As a building material, metal expanded mesh (also known as steel mesh, tensile mesh and punching and shearing mesh) has the characteristics of light transmission, economy, firmness, easy manufacture and beauty. It has a wide range of applications, such as decorative curtain wall, steel platform, hanging mesh in plastering layer, breast board, ceiling, indoor partition, furniture, vent, etc. The installation and use of metal expansion mesh can refer to the recommended national standard steel mesh (GB / T 33275-2016). While referring to this standard, other metal expansion mesh should also comply with the corresponding national standards or industrial standards of other materials.

1. Material and surface treatment

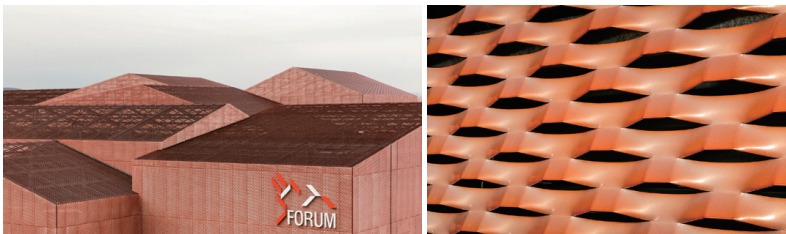

The expanded net is generally made of metal plate or metal coil. The size of the plate is related to the plate width of the raw material. The transverse direction is basically the same as the original plate width, and the long direction is longer than the original plate width. The commonly used materials are low carbon steel, stainless steel, aluminum and weather resistant steel. Other materials such as brass, titanium and nickel are also occasionally used, but most of them are steel and aluminum expanded mesh. Generally, metal or alloy plates with certain toughness and bendable folding can be processed into expanded mesh in theory. The expanded nets made of different materials are different in physical and chemical properties, mechanical properties, installation methods and overall effects. For example, the overall strength of aluminum expanded mesh is lower than that of steel expanded mesh with the same specification and size, but the aluminum mesh is lighter and the anti-corrosion performance is much better than that of steel mesh. Therefore, the material shall be selected according to the actual engineering situation. Metal expansion net belongs to the cold processing of metal plate. Due to the problem of anti-corrosion and rust prevention, the metal needs surface treatment. Different surface treatment directly affects the apparent texture and physical and chemical properties, and the cost also varies greatly. Common treatment methods, such as galvanizing, fluorocarbon spraying, powder spraying, anodizing, etc., are suitable for the treatment of metal material surface, and basically also suitable for metal expansion mesh. For example, Le forum, located in the cultural and sports community center of St. Louis, France, uses the varnish added with copper powder to paint the aluminum expansion net. The surface forms a red copper color while maintaining the luster of aluminum. The materials of the facade respond to the industrial history represented by the red roof of the buildings around the area.

2. Manufacturing process

The manufacturing technology of expanded mesh is relatively mature, mainly using punching and shearing technology. The punching and shearing machine starts from the edge of the metal plate, the metal plate placed on the platform is stretched while being cut, and the punching and shearing machine is lifted up to process a whole row of mesh. For each punching and shearing, the machine tool pushes the metal plate along the longitudinal direction according to the stem wire width, and the cutter moves along the transverse direction and half of the long pitch, and then punching and shearing downward. After the expanded mesh is formed, it is sent to the roller room of the leveling machine for leveling, and then sent to the cutting machine for cutting according to the required plate width. Finally, the surface is treated according to the demand. The expansion net belongs to cold processing in the manufacturing process, which can not only reduce the waste of original plates and avoid the generation of manufacturing waste, but also form larger plate width and more kinds of spatial structure only through physical processing.

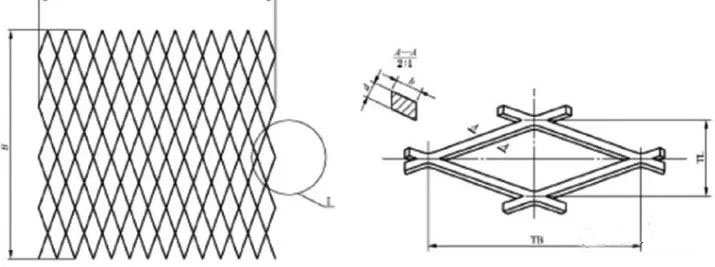

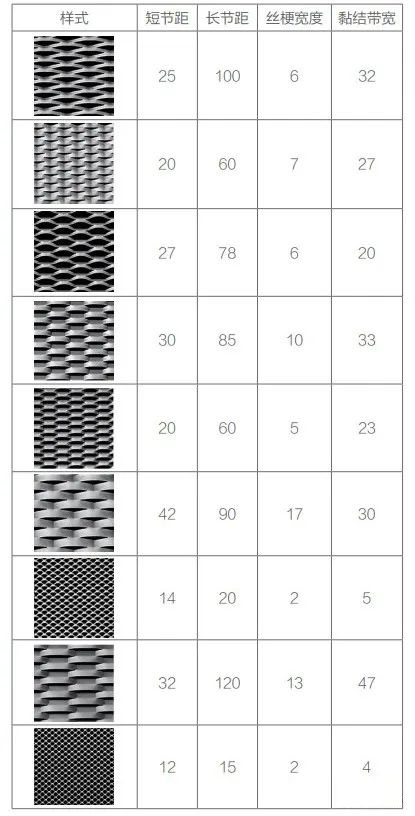

3. Form size

The appearance style of expansion net is mainly divided into vertical expansion net and horizontal expansion net. The horizontal expansion net includes reinforced expansion net and unreinforced expansion net (also known as batch swing net). These two kinds are mainly used as building auxiliary materials in the painting layer, which are not within the scope of this paper. The structural dimension parameters of the longitudinal expansion network include: mesh size - mesh length (L), mesh width (b), mesh size - short pitch (TL), long pitch (TB), silk stem width (b), metal plate thickness (d) and bonding bandwidth (n). Where, short pitch and long pitch refer to the size on the projection plane. The effects of different sizes and specifications of longitudinal expansion nets are very different. In the actual engineering design, it can be selected and used with reference to the common forms and sizes listed in the national standard, or it can be customized according to the actual needs. As shown in Table 1, the dimension parameters can not directly reflect the actual style, so in the actual project, the parameters are only used to describe the materials with the solid template.

△ the figure above is the structural dimension diagram of the expansion network

△ the above table is the size parameters of expansion nets with different sizes

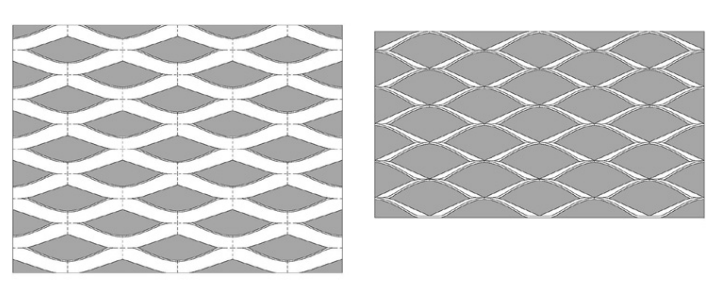

4. Pass type

The expanded mesh has various forms, including diamond hole, fish scale hole, hexagonal hole, circular hole, special-shaped hole, combined hole (such as tortoise shell hole), etc. The hole type is the description of the appearance style and the common name agreed in the industry. It is not accurately defined in the national standard, and even the directivity of different manufacturers is not unified. The basic form and size can be specified in the design documents, and the corresponding detail drawings can be drawn to intuitively express the actual effect.

5. Thickness

The form characteristics of the expansion network determine that its actual space thickness is greater than the thickness of the metal plate itself, which can be roughly calculated according to Formula 1:

Note: H space thickness of expansion net, TL short pitch, B wire stem width, D metal plate thickness.

Due to the difference of pass type and flexibility of metal material, the space thickness of the actual expansion network may be different, but it can be basically calculated by this method. When the expansion net is used in the actual project, angle steel (angle aluminum) or channel steel (channel aluminum) is often used for edge trimming. Therefore, it is necessary to ensure that the expansion net will not exceed the size of angle steel, and the size of angle steel will also affect the overall calculation of curtain wall.

6. Pedicel inclination

The inclination of each section is determined by the short pitch and the width of the silk stem in the longitudinal expansion network. The included angle between the inclination of the silk stem in the longitudinal section of the element grid and the direction of the plate surface is about arccos (2B / TL). When the design needs to block the field of vision at some specific angle or the sunshine in a certain period of time, the angle of the expanded mesh unit mesh wire stem should be determined.

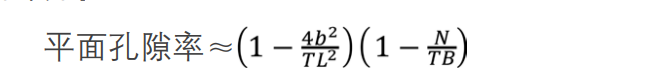

7. Porosity, weight, expansion

Expansion rate is the concept defined in this paper, which refers to the percentage of the expanded size of the expanded net relative to the original plate. The longitudinal expansion network only expands in the longitudinal direction, and the expansion rate refers to the change in the longitudinal direction, which is about short pitch / twice the pedicel width (TL / 2b). The expansion rate is mainly used in production material preparation and cost calculation. Expanded net is a kind of space material. Its porosity refers to the plane porosity of the vertical projection of holes on the plate surface, or the spatial porosity of the space surface where each hole is located. The plane porosity can be roughly calculated according to formula 2.

△ the above figure is the plane projection and spatial projection of the expansion network of the same specification

In order to simplify the calculation, the influence of the thickness of the plate itself is ignored. The thicker the plate, the greater the inclination of the silk stem, and the greater the value of the calculation result of the formula. However, when used as decorative materials, the thickness often does not exceed 4mm, so the deviation of the results is basically within the acceptable range. Porosity is mostly the material selection basis for sun shading, sound absorption, sound insulation, ventilation and other needs. If more accurate porosity data is needed in the process of use, more in-depth simulation analysis is still needed in the actual project. The spatial porosity is affected by the spatiality of materials and the bending change of elements, so it is difficult to calculate by formula, but the results can be obtained by three-dimensional modeling of local elements. Moreover, due to the spatial characteristics of the network, the general spatial porosity will be much greater than the plane porosity.

The expansion net belongs to cold working materials, and the weight basically comes from the raw materials themselves. The theoretical weight ≈ the theoretical weight / expansion rate of plates with the same thickness. In practical engineering, the cost of expansion network is often calculated by weight

2、 Performance and function of expansion network

1. Mechanical properties

Compared with other translucent metal materials (such as perforated metal plate and metal woven mesh), the expanded mesh has better out of plane strength, its total thickness is greater than the raw metal plate, and has better moment of inertia, which makes it more suitable for installation on the facade bearing wind load. There are few studies on the mechanical properties of expanded mesh in China, and the correlation system between its mechanical properties and the thickness, size, plate width and material of expanded mesh has not been completely established. However, it is obvious that the overall thickness, stem width and raw material plate thickness have an impact on the overall strength.

Many factories in China produce heavy steel mesh for load-bearing, but there is no standard or other basis to explain the relationship between its bearing capacity and actual size, which restricts its application as a load-bearing member in formal engineering. The relationship between the bearing capacity and the expansion size is explained in the steel mesh standard of the former Soviet Union. Compared with the commonly used metal bearing material steel grid plate, the bearing capacity performance of steel expanded mesh is better than that of steel grid plate under the condition of the same material and weight.

At present, in domestic practical projects, it is difficult to directly use the expansion net as a load-bearing component, but when it is used as the facing material of breast board and curtain wall, it will still involve the calculation of lateral thrust resistance and wind load. The nonlinear stress condition of the expansion material makes it difficult for general institutions to accurately calculate it, which can only be determined by the supplier's engineering experience and actual tests. The author proposes to start the special research on the structural strength of the expansion network and introduce more specifications and standards, so as to promote the application of the expansion network.

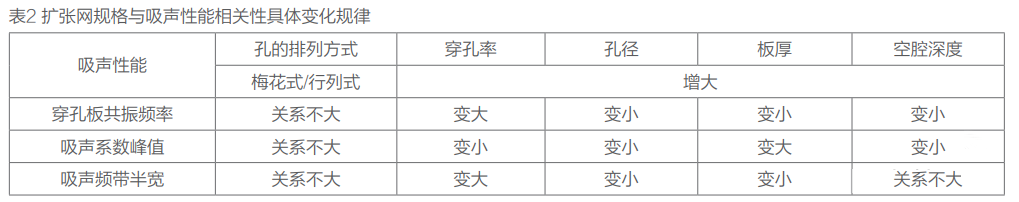

2. Sound absorption performance

As a sound-absorbing material, expansion net has been applied in fields other than architecture. For example, the sound absorption mechanism of mechanical equipment exhaust outlet and sound equipment surface is the same as that of perforated metal plate, which belongs to resonance sound absorption structure.

There are few studies on sound absorption of expanded net in China, but the research on resonant sound absorption structure of perforated plate is very comprehensive, and its conclusion is also applicable to expanded net. Compared with other sound-absorbing materials, metal expansion net has the advantages of low price, corrosion resistance, firmness, fire prevention, moisture-proof, beautiful appearance and easy cleaning. It is more suitable for noise environments such as factories, equipment rooms and roads.

The resonance sound absorption structure needs to interact with the cavity formed by the back air layer and the base layer. The structure has the maximum sound absorption coefficient near the resonance frequency. The farther away from the resonance peak, the smaller the sound absorption coefficient, and the maximum sound absorption coefficient is about 0.3 ~ 0.6. The resonance frequency of the metal expansion network is mainly in the medium and low frequency, so it has a good sound absorption effect on the medium and low frequency noise. The specific change law of the correlation between the expansion network specification and sound absorption performance is shown in the table below.

With the increase of cavity depth, multiple resonance frequencies will appear in the perforated plate resonant sound absorption structure in the frequency range of 50 ~ 6400hz. The greater the cavity depth, the more the number of resonance frequencies. Since the sound absorption coefficient of the resonance sound absorption structure decreases sharply near the resonance frequency, if you want to broaden the range of sound absorption frequency band, you can add porous sound absorption materials behind it. At the same time, it should also be noted that when the perforation rate is greater than 20%, the acoustic effect is ignored. Therefore, when the expanded net is used as the sound-absorbing material, the light transmittance of the expanded net will also be reduced. In practical engineering, the appropriate expansion network should be selected according to the actual sound absorption requirements or more accurate acoustic analysis.

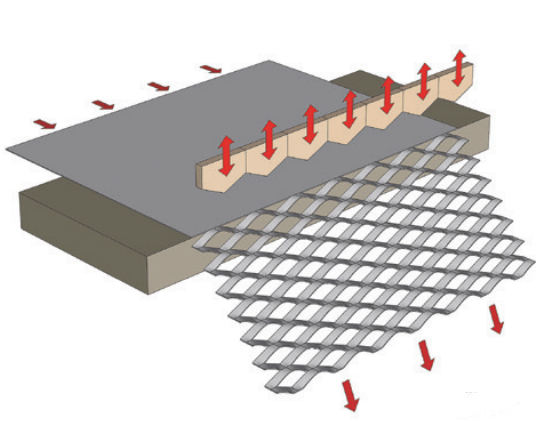

3. Sun shading, heat insulation and ventilation

When the expansion network is used as the enclosure structure, it forms the first protective barrier between the building and its surrounding environment, provides sun shading, heat insulation and ventilation, and can effectively improve the energy-saving level of the building in the humid / hot environment. As a passive energy-saving means, the expanded net decoration layer takes into account the overall thermal performance and visual comfort of the building. Compared with the complex mechanized shading system, the skin of the expansion net can define the appearance of the whole building and reduce building energy consumption. At present, there is no research on sunshade and heat insulation of expansion net in China. This paper quotes some foreign research conclusions.

(1) The direct radiation of sunlight has a great impact on the building. The special angle of the stem in the spatial structure of the expansion network has an obvious barrier effect on the direct sunlight in a specific section. At the same time, diffuse light can be introduced to ensure a healthy visual environment inside the building. As a metal product, people are more worried about the radiation effect caused by the temperature rise of the expansion network under solar radiation. On the one hand, the influence of color and gloss on the absorption of radiant heat should be considered in the design. For example, light colored smooth materials can better insulate heat; On the other hand, the ventilation effect formed by the gap makes the expansion network usually not reach very high temperature.

(2) The shadow pattern caused by the sun being blocked by the expanded net is also one of the influencing factors. Larger holes will form mottled shadows and produce dazzling feeling. Therefore, they are not suitable for spaces requiring precision work, such as laboratories, workshops and offices. They are often used in sports, leisure, cultural and commercial places.

(3) Compared with other sun shading facilities such as metal perforated panels and shutters, due to the better strength brought by the spatial structure of the expansion net, higher porosity can be adopted to obtain more transparent vision and better ventilation effect. Thinner metal plates can also be used to save materials. Although the finer stem wire can provide more uniform lighting effect, it does not have the effect of heat insulation and sun shading, which should be comprehensively considered in engineering design.

(4) The specification parameters of the expansion network itself, the relevant parameters of sunlight (including the direction of incident light, solar azimuth and solar height), and the color of the expansion network are the three main factors affecting the sunlight transmission of the expansion network. Due to many variable conditions, it is difficult to show a strict linear relationship between specific parameters or parameter groups and shading effect. Therefore, when the project needs accurate shading design, it is necessary to conduct specific simulation. As an external sunshade, expansion net is more flexible in most practical engineering applications. For example, the M2 Technology Building of Salamanca University in Spain designed by Sanchez Gil Arquitectos adopts an open external ventilation double-layer curtain wall. The outer layer is a mechanized and movable expansion network to control the sunlight emitted into the building. The inner layer is the actual indoor and outdoor boundary. According to different orientations of the building, the double-layer curtain wall is correspondingly provided with cavities of different depths, which are shading, heat insulation and ventilation; The "woning k-14" project in Amsterdam adopts a form similar to the window guard outside the window, which can present a complete facade when closed, completely block the window, and can be opened and closed manually according to the needs of daylighting.

3、 Expansion network support system

As an external decoration, the expanded net is still a kind of building curtain wall. Its installation process is simple and fast. The net is formed in the factory. It can be directly fixed on the supporting structure system without cutting on the construction site. The permeability of the expansion network determines that the supporting system behind it will appear together with the expansion network.

The expanded net curtain wall system is a component type open curtain wall, which can refer to some specifications of metal plate curtain wall, but the expanded net as a space material is different from the conventional metal plate material. The author believes that on the premise of ensuring safety, some technical requirements in the specification can be appropriately relaxed. For example, in terms of wind resistance performance, the expansion network has certain out of plane strength and high porosity. Although the strength is difficult to quantify temporarily, it is significantly better than metal plates with the same material and thickness, or even perforated plates with the same porosity. If the deflection calculation requirements of the specification are met, the frame material size will be large, which will not only affect the beauty, but also cause a certain degree of waste. When the expansion net is directly used as the peripheral protective layer, its safety performance is particularly important. For example, some veranda buildings directly use it as an outer enclosure. At this time, we need to focus on its impact resistance and bearing capacity and strictly implement it. At this time, the strength of the expansion network should be calculated as a special project and tested.

Due to its remarkable corrosion resistance, aluminum is the most common raw material of expansion mesh, which is similar to aluminum plate curtain wall in structure. The conventional and more economical keel system material is galvanized steel. Because the steel and aluminum cannot be welded, the aluminum expansion net can be fixed on the aluminum frame, which can be bolted or riveted with the main keel, or directly fixed on the main keel through adapters. Intuitively, the common expansion network system can be divided into framed system and frameless system.

Expansion network in architecture

Practice in Yanqing Winter Olympics project

(the article is quoted from the paper "Application Research of metal expansion network and Winter Olympic engineering practice in the context of architecture". The author is Zhang Siteng, Li Xinggang, Xia Lu and Zhang Zhe of China Architectural Design and Research Institute Co., Ltd.)

Strong system is committed to the R & D, production and sales of fabricated refined steel system curtain wall materials, perfectly catering to the development concept of large permeability, large span and slimmer in the current curtain wall industry, and providing a one-stop solution for building curtain wall! The company now has more than 40 patents related to refined right angle steel profile production equipment, production process and product appearance! Xichuang system takes "everything is for the safety of human life and property" as the mission and pursuit of the enterprise to further improve the human living environment.